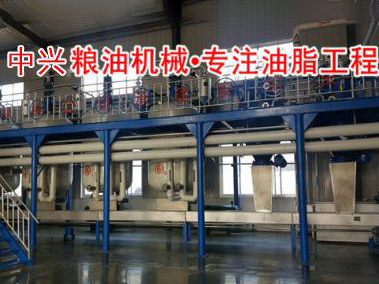

50-300T/D冬化脱蜡成套设备

50-300T/D complete set of equipment for winterization dewaxing

冬化脱蜡是将油脂冷却使油脂中凝固点较高蜡质结晶析出的过程。葵花籽油、玉米胚芽油、米糠油等含蜡质较高的油品经脱胶、脱酸、脱色、脱臭等精炼工序后, 在气温较低的冬季仍会有少量固体脂呈絮状沉淀析出,影响油品的外观和使用,为了杜绝这种现象,这些油品需增加冬化脱蜡加工工序。冬化脱蜡在缓慢地搅拌下,在一定时间内将油脂冷却至4-6℃左右,使蜡质形成较大结晶,并分离析出,再经过滤,将液态油和固体脂肪分离开,从而提高了油脂的食用品质及营养价值。

Winterization dewaxing is a process of crystallization of wax with high freezing point by cooling oil. For sunflower oil, corn germ oil and rice bran oil with high wax, after degumming, deacidifying, decolorization, deodorization and other refining processes, a small amount of solid fat will be flocculent precipitation in cold winter, and affect the appearance and use of the product. In order to put an end to this phenomenon, these products need to increase the process of winterization dewaxing. Under stirring slowly, winterization dewaxing will cool the oil and fat to around 4-6 ℃ in a certain period of time, and the wax forms a larger crystal, separation and precipitation, then through filtering, the liquid oil and solid fat separation, thus improve the edible quality and nutritional value of the oil and fat.